This page was last updated on Jun 18, 2012

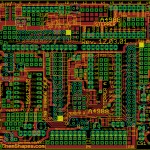

Eagle Cad files of the CS-1Top copper trace trace layout (Done in EAGLE CAD) below:

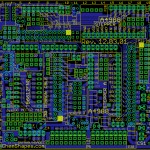

Bottom copper trace trace layout (Done in EAGLE CAD) below:

Populated view below:

CS-1 Assembly manuals:

Main Cs-1 Assembly manual here:

Chemshield_assmbly_ instructions.

CS-1 30 way Ribbon Cable Assembly here:

Assembly_instructions_ribbon_harness_Rev_12_06_12

CS-1 Opto Interrupt PCB’s assembly manual here:

1:37 am, August 24, 2011nst /

Thank you

Really deserves thanks to you and showed you how your experience in machine building

My English is simple I hope to accept my thanks in this sense

2:11 pm, April 4, 2012tj /

@nst

nst ,

It IS my pleasure hope you can all enjoy the fruits of our Labor

TJ-

6:03 pm, October 26, 2011Eduardo /

Where can i purchase a ChemShield?

Thanks

Eduardo

6:45 pm, October 26, 2011TJ /

Nst,Thank you.

Eduardo

The CHEMSHIELD is currently only in prototype/beta testing phase.But hopefully next year we will be selling them as full integrated Shield for the “Arduino mega 2560” as a modular unit

TJ.

10:42 pm, October 26, 2011Eduardo /

Thanks TJ,

Whenever you make it available please let me know ( eduardomagtoy@gmail.com )

Eduardo

San Leandro, California.

6:37 pm, November 4, 2011Vince /

TJ.

I am interested too in this amazing project.

If this is still going on, please include me to get a CHEMSHIELD .

(assyexh@gmail.com)

Thank you for sharing.

Vince.

8:21 pm, December 21, 2011Daniel /

Cool printer. I need one of these also. I am also a master goldsmith and have designed a line of jewelry that each piece will have some alterations in it, which makes it a pain for hand carving, but perfect for a 3D printer. I hope to get one ASAP.

10:03 pm, December 21, 2011tj /

Hi daniel welcome

Please stay with us ,as we finish the software through next year we will be close to get some kits together soon

TJ Snyman

2:48 pm, January 8, 2012Daniel /

High TJ,

Do you think you will have a kit (even a beta that can be upgraded later) available by mid February? I need to get started an a project and so need a 3D printer ASAP. Also do you have a ballpark estimate on price of everthing to get started ( kit w/ software, resin for lost wax casting, post cure if needed, etc.), so I can budget the money or get funding as needed? This looks like a great project you have going here.

Daniel

3:17 pm, January 10, 2012tj /

Daniel

That is a little soon ,I don’t think we will have a kit ready for sale mid Feb,2012 . We are still sorting out some Software and PCB layout bugs.

TJ Snyman

5:38 pm, March 28, 2012VInce /

Well done TJ,

You did an awesome job like you always do.

I hope to get a chemshield too.

Vince

2:09 pm, April 4, 2012tj /

@VInce

Thnx, Vince many, many hours went into that , I had no idea it was gonna take that long , I am very happy with it.

7:34 am, April 4, 2012Rod /

Hello, do you intend releasing the PCB EAGLE files for those that want to make their own boards? I for one would like to now….

2:07 pm, April 4, 2012tj /

@Rod

Rod

Yes absolutely ,I just havent uploaded the files yet. will do soon,

tj-

1:39 pm, April 16, 2012William Janicke /

Hello, When will the sheild be available?

4:44 pm, April 16, 2012tj /

@William Janicke

William

We are testing them right now, and everything is smooth sailing so far! ..My guess in about 4-5 weeks. For now only a ” loose kit ” with shield and loose components will be available.

tj-

7:35 pm, April 16, 2012William Janicke /

Whoa! I am excited!

8:48 pm, June 4, 2012Ross Jacobs /

anychance of a loose kit yet? going to be such a awsm project 🙂

9:41 pm, June 4, 2012hradec /

@Ross Jacobs

The kit is coming really soon… we just want to have the software fully working with it so we can release it without any recalls, you known?

We do have some shields available though, if you’re interested!

Ask for it in the forum… it’s easier to reach us there! 🙂

4:52 pm, June 5, 2012Vince /

Can I to get a Chemshield yet?

Kindly advise.

Vince

1:10 pm, November 10, 2012Etienne /

Good morning,

I plan to design 3D printer thanks to an UV resin from 1 to 6 video projectors.

I was in the maintenance of 3D printer to 3D System, I realized prototypes of machine SLA and MJM.

My purpose would be to create 3D printers :

Small size ( 10cm * 15 cm / ± 0,1 cm)

Large size ( 100cm * 100cm / ± 1 mm)

Without specific maintenance ( open source software and parts inexpensive/ easy to find)

I have little knowledge in the world of data processing, so what do you recommend to a machine with a video projector and a PCB Arduino if possible.

Best regards,

Etienne JACQUEMIN

Email adress : bricoloman21@hotmail.fr

FRANCE

8:14 pm, November 15, 2012hradec /

Haute Etienne…

Our goal is to do exactly that… a Arduino/Consumer projector DLP 3D Printer!!

There’s tons of information in this website about our whole research process, so fell free to dig into it!

We do have an early Arduino Shield prototype to control our prototype, but as we’re still testing it, we didn’t publish the specs for the PCB yet. Sorry!

Stay tuned because we will have some good news soon!

-H

1:21 pm, November 10, 2012Etienne /

If you have any question on

Vflash projet 1500 (DLP Printer)

Tray Pad

Build Pad

Mécanical systeme

….

8:15 pm, November 15, 2012hradec /

Actually, I do have one question:

Do you known what material they use in booth the tray and Build pad? Do you have an idea about the mechanism they use to release the printed slice from the glass?

8:02 pm, January 9, 2013Etienne /

C ‘est a Film (Teflon I assume) but it is not to fix.

A space of 2mm is between the window pane and the film Teflon, a pomp has space come to glue together it against \.

For the extraction the pomp it cuts what the rounding up ) and takes off the room. I am going to see to recover an old film and the analysing …

And brilliant for good news ^^

to Send a mail me if you want schemata