Last updated JUL 14, 2011

This is a very controversial subject defended by a lot of purists. Here is our take on it.

For most application the Ultra Violet or visible light curing method is by far superior and much faster to any other rapid modeling methods. The name 3d-printing is actually a misnomer. a Better title for it is ” Layered UV cured modeling” . Even though this method uses resin for every layer buildup it is not mechanically applied at every layered level. Becaus it is a liquid at low viscosity ,it uses gravity to fill the building gap for the next layer of curing. For that reason we do not categorize it as deposition modeling . It has great resolution , and uses minimal moving parts.

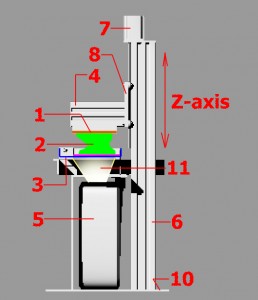

Fig. 1. The basic concept of UV light curing,1-Stage (building platform),2-The model being build,3-The Vat containing the resin,4-horizontal beam,6-Main Z-Axis collumn,7-Stepper motor,8-Carriage plate,10-Base,11-Projection beam

http://en.wikipedia.org/wiki/Rapid_prototyping

So what is a rapid prototype modeling by light projection and how does it work?

The purpose of it is to rapidly ( a few hours)fabricate/grow an exact replica of a 3 dimensional computer aided design drawing(CAD). It is normally a conceptual or working model for the industry. Scientists ,architects,dentist ,jewelelers etc. make very good use of it and for the first time this will now be available to the hobbiest,the D.I.Y’s and tinkerers . Any type of model can be build with it with no limitations to undercuts ,hollow structures or curvature. It builds a model in a 3 dimensional hard durable solid layered format in resin ,rubber or wax. (now other materials also became available). The model is build upside down with the base attached to the hatced blue platform.

The software interface (see link below) starts the process by slicing a 3d CAD drawing into thousands of horizontal sliced layers and generate a photo image for each cross section in a seqential order. For example if the model was a sphere ,the images would start as a small tiny round white dot on the bottom and grow sequentially bigger per layer until it gets to the center slice(the biggest) .Then it will get smaller again (per layer) as it goes to the top of the sphere. . The last sliced image wil be small again. Each image is used to seqentially build a one layered cross section at a time. Each layer is formed by hardening a layer of resin by the printer as decribed below:

Refer to the above illustration Fig. #1 : A Light curing resin (usually Ultra violet(UV) sensitive) is poured into a shallow square vat/container (shown in blue color).The bottom of the vat is made of clear glass . A building platform (Yellow) is lowered into the liquid resin until it almost touches the bottom glass (hairline space above). A projector projects the first image sliced (cross section #1) of the 3d CAD drawing in white light (or uv) through the glass onto the building platform surface for about 8 seconds. As the thin sandwiched layer of resin between between the glass and the building surface recieves the light, it cures to a plastic consistency(polymerize). This first layer is importand ,It forms the base of our model wich is now glued to the building platform surface. The printer stops projecting and let the computer know to move the platform up another hair thickness (0.01mm) .The printer calls for the next image and projects the next layered image.The process repeats itself over many thousands of times with a new image every time…….. Layer after layer the model is build up ( like a thick stack of paper) to form the solid model.

This process continous until the whole model (green) is extruded from the resin vat.The model is build upside down, as it extrudes from the base first.

A highly detailed model (high resolution) of 2 inches high (50mm) usually consist of thousands of layers. Needless to say that the whole process is computer controlled and can take up many hours to build a small 2 inch model.

___________________________________

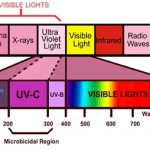

Ultraviolet (UV) light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm.

There are three types of Ultra-violet light :

UV-A : With wavelength 400-320 nm is less intense than UV-B, but is more penetrating to the eye reach and damage the retina easily

UV-B : Wavelength 320-286 burns the skin and damages the cornea and ocular lenses.Half of it does not go through window glass as far as I read and researched.

UV-C : filtered off by ozone layer

Here is the a the lightwave spectrum ,we are going to focus on the Ultraviolet

***********************************************

Other links:

2-….Here….. is a good link if you want to dig really deep in the definitions.

Companies that does RP modeling

1-http://www.redeyeondemand.com/Materials_PolyJet_photopolymers.aspx

11:19 am, August 24, 2011reprap101 /

Have built a humble 3d printer recently.

Please observe.

Photos at

https://picasaweb.google.com/118257776948658176570